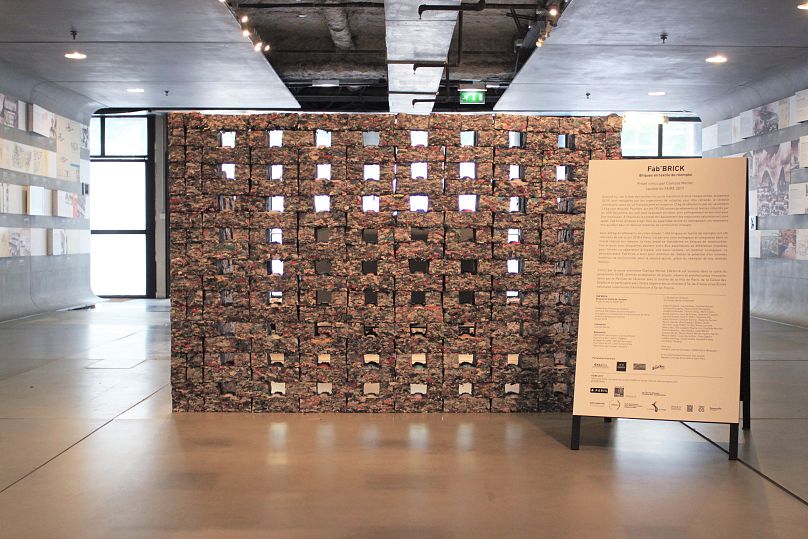

In partnership with Media City, Qatar. “I took two t-shirts, I compressed them into a brick, and it held. That’s how the idea of FabBRICK emerged!”

Meet the French eco-chic architect crafting fashionable bricks

SCENES shines a spotlight on youth around the world that are breaking down barriers and creating change. The character-driven short films will inspire and amaze, as these young change-makers tell their remarkable stories.

It has been well-documented that the Fashion industry can harm the environment. Fast fashion clothing is typically cheap to produce and designed with a limited lifespan in mind. According to a UN report, the habit of throwing clothes away has increased, and the number of times a garment is worn has declined by more than 35% in 15 years. This leads to multiple ethical and sustainable issues, including long-term and potentially irreversible environmental damage.

The birth of FabBRICK

Clarisse Merlet, an ingenious entrepreneur, defied the odds and thought outside the box to create a solution to the textile waste problem. Brimming with determination, she embarked on a quest to convert discarded textiles into something extraordinary – bricks!

Interestingly, her initial inspiration for recycling clothes did not stem from the textile industry’s significant waste but rather from the desire to construct bricks without using concrete.

“I looked into how I could make a brick out of something else, like waste. I thought of the textile industry, which is extremely polluting, right after the construction industry,” Clarisse tells SCENES.

She recalls the exact moment when her idea first came to mind. “I took two t-shirts, I compressed them (into a brick), and it held. That’s how the idea of FabBRICK emerged!”

Textile Recycling Revolution

The beauty of Clarisse’s concept lies in its simplicity. Combining shredded textiles with a gluing substance, she discovered a novel way to transform these materials into sturdy, eco-friendly bricks. During the initial production process, she learnt that mixing different types of textiles can be challenging.

“Today, when you want to recycle textiles, the main difficulty is that you can’t really mix different materials (together). Often, recycling companies only take cotton or polyester. And you have to remove all the hard parts of the clothes, like the buttons and zips, because not everything goes through the recycling machines,” she explains.

Clarisse had a desire to work with a multitude of materials, even those that were tough to manage. Her simple goal was to reduce waste by utilising every possible resource.

“Eventually, we succeeded in inventing a process that uses all types of fabric. So, we mix cotton, polyester, viscose, and all the others. We can put the entire garment into the grinder. There is no need to disassemble beforehand,” she says. “We don’t remove the buttons; we put everything in it and create zero waste. For me, it was obvious just to put everything as is.”

Sustainable Building Alternative

This new approach not only addresses the issue of textile waste but also provides an alternative building material that is sustainable and resourceful. These textile bricks offer many benefits that traditional bricks cannot match.

The production process significantly reduces dependency on conventional resources such as concrete, which is known for its negative environmental impact. Moreover, the repurposed textile bricks possess excellent insulating properties, making them a smart choice for construction.

“Clothes are made to insulate the body, and therefore, by recycling clothes, you can also insulate interiors, both acoustically and thermally,” Clarisse says. “Cotton clothes will be more insulating,” she adds.

Paris: The Fashion Capital

FabBRICK is based in Paris and sits comfortably amongst the top fashion houses. The location was optimal for client visibility.

“I find it interesting to be able to welcome them here. I show them the showroom, we have a meeting, and directly after, I can show them the production,” Clarisse explains.

“Production is not completely separated from the showroom. It allows me to be completely transparent about the work. That’s why I found it important to settle in the heart of Paris,” she tells SCENES.

Thinking outside the brick

Clarisse’s venture goes beyond construction. She envisions using these bricks to make outdoor furniture, for use in gardening, and for art projects.

“With these bricks made with recycled textiles, we can create stools, small tables and large libraries,” Clarisse explains. “With thinner bricks, we can decorate a wall and improve the space’s acoustics since bricks are excellent insulators.”

Clarisse has demonstrated that with hard effort, passion, and a drive to change the world, the impact can be limitless. FabBRICK has helped companies and consumers change their perspectives and reconsider discarded fabrics.